NEW ASSEMBLY EQUIPMENT WITH INTEGRATED ELECTRICAL TEST

Case: Design and implement automation equipment to fully assemble and test a control valve with 8 unique components, with a 2.5M EAU capacity (5.7 second cycle time), using no direct labor.

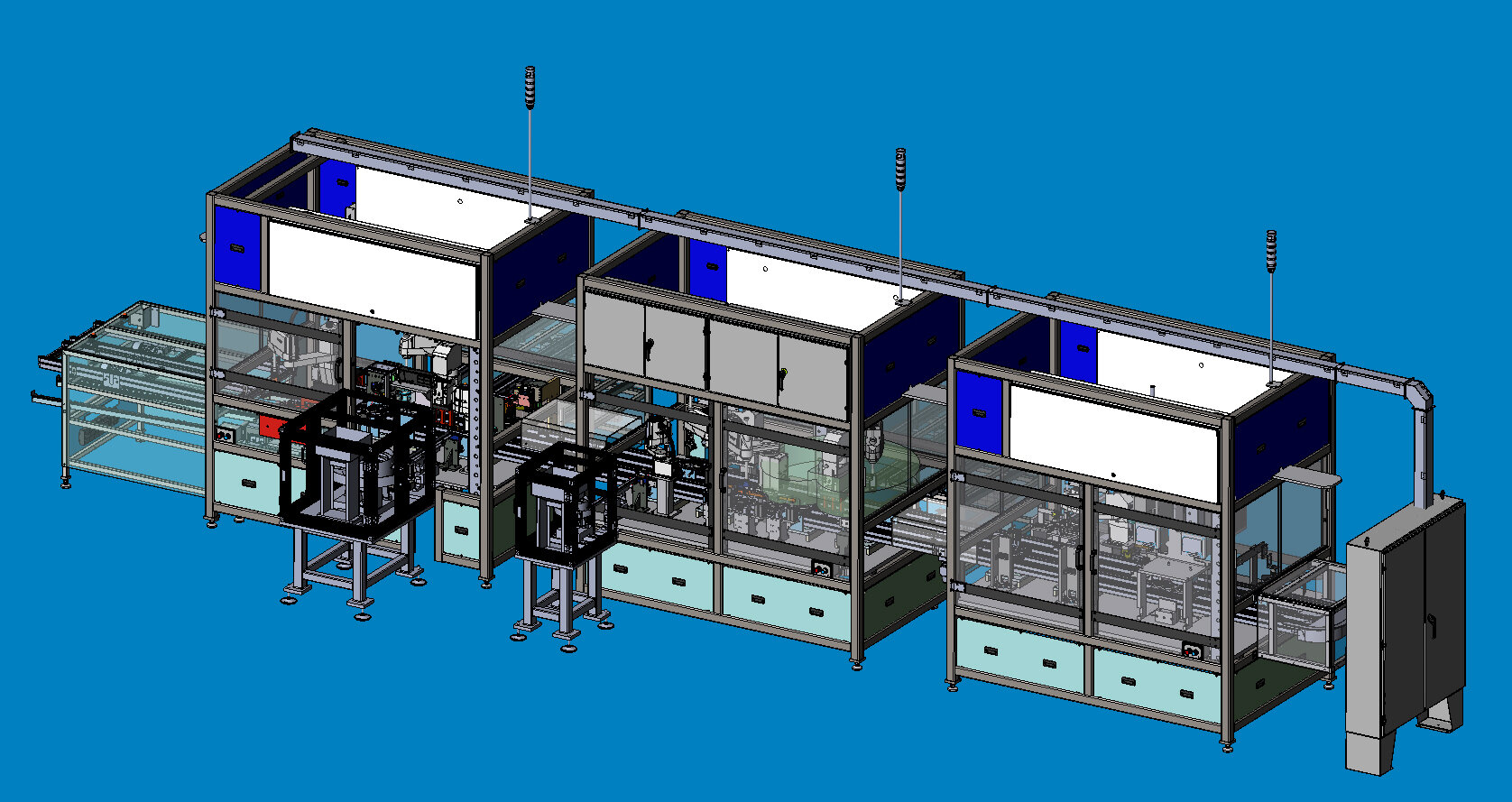

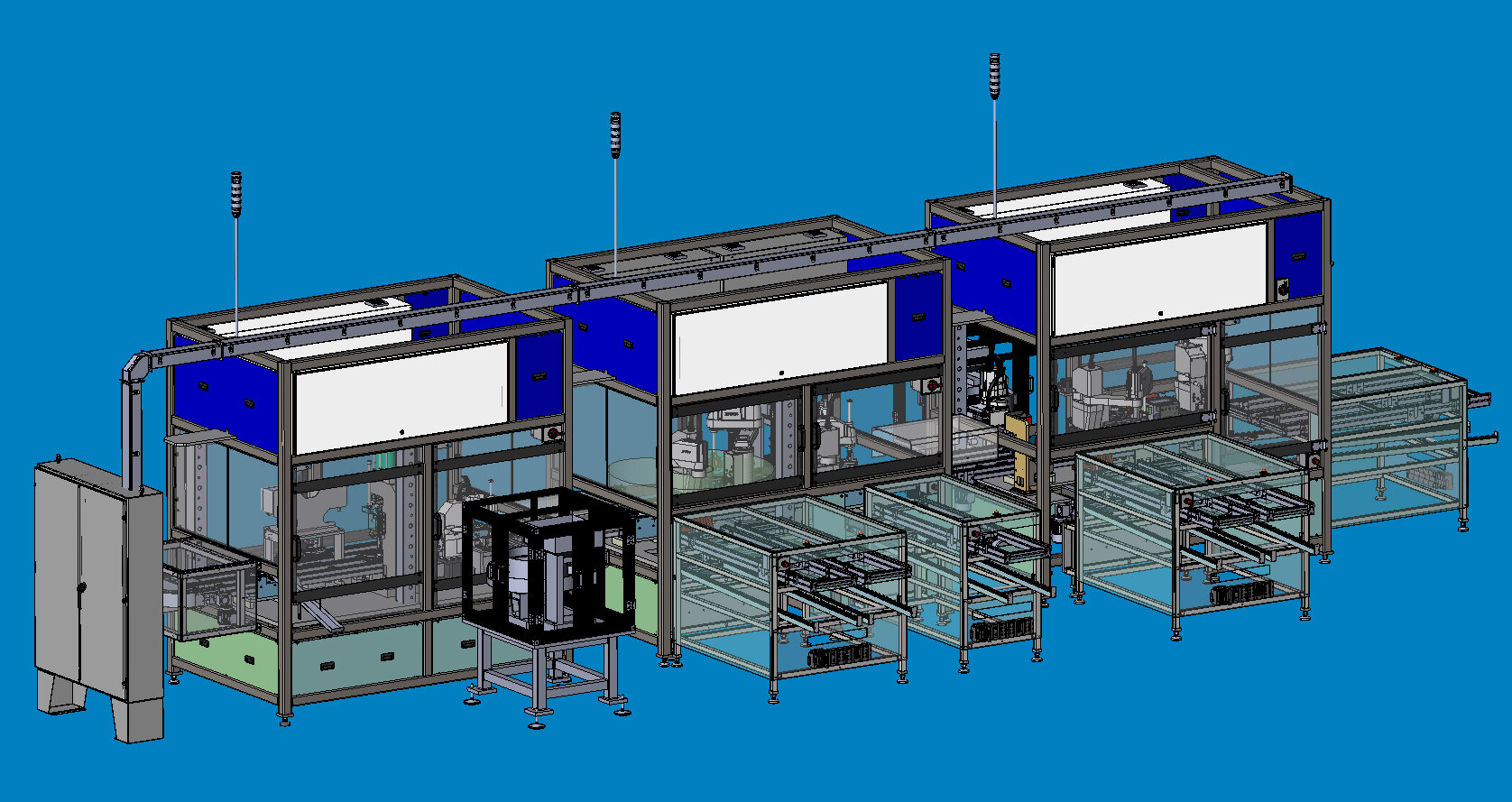

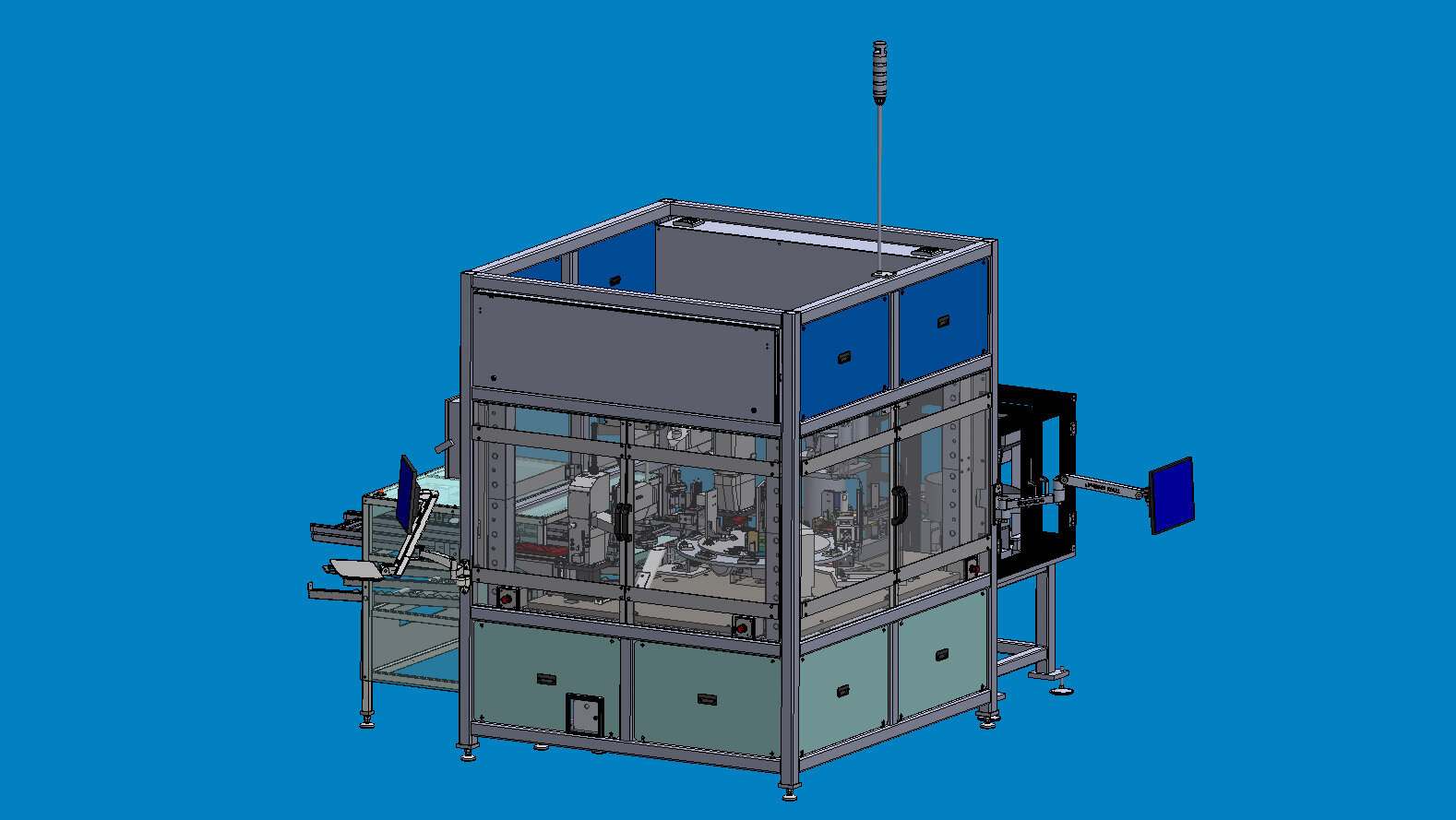

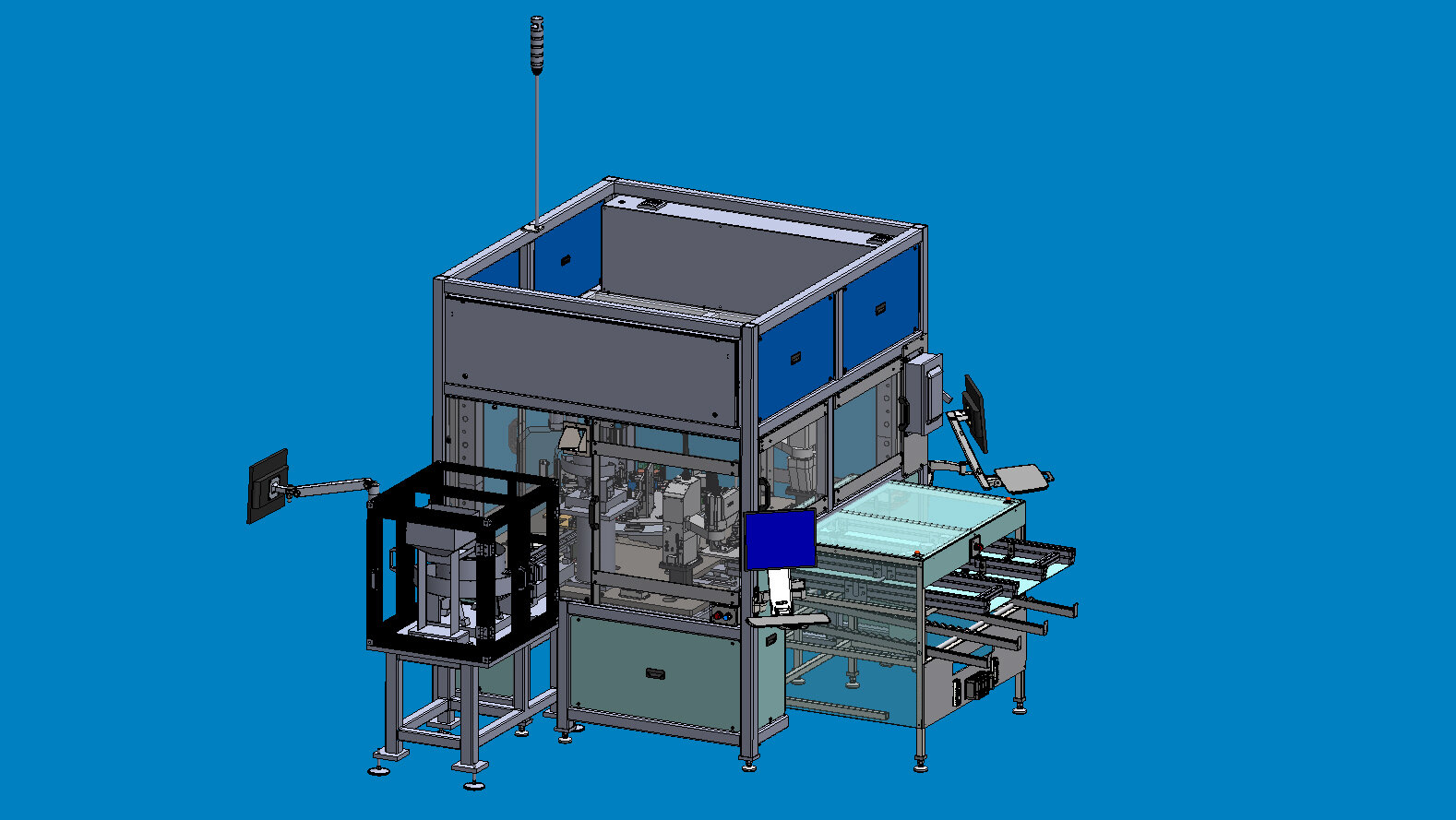

Result: Two unique automation machines designed and produced. The first machine creates a sub-assembly of 3 components and includes 2 Epson robots, 2 Cognex vision systems, a hydraulic press station, and an assembly verification station.

The second machine builds this sub-assembly along with all remaining components into a completed control valve. The machine utilizes multiple Cognex vision systems to assist with proper assembly, 8 Epson robots, including one with vision guidance, a hydraulic press with proportional force & distance monitoring, 2 Cincinnati Test Systems air pressure decay testers to validate seal integrity, electrical testing to validate solenoid characteristics, 3 performance test stations to proportionally test force and position characteristics vs. applied current, using internally developed software, and a Datalogic laser for serialization.